UEC-2B

UEC-2A was used for testing it revealed a number of design flaws that lead to the improvements for UEC-2B.

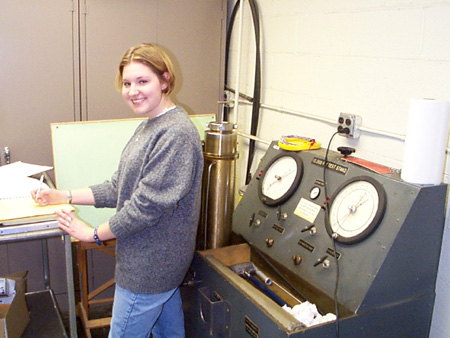

Photos and specifics of UEC-2A

UEC-2B currently setup to log temperature and pressure, and store the data in a four (4) channel data logger by Onset Computer.

UEC-2B before deployment on Submarine NR-1 at the end of April 1999.

The equipment first deployed on the UEC-2B. The D cell batteries power the data logger and temperature transducer. The12 volt lead-acid battery pair power the pressure transducer drive circuit. The power supply to this can be much smaller. Due to time constraints we took the brute force solution to the problem.

We could not find a pressure transducer designed for a fully immersed environment which was not custom built costing multiple hundreds of dollars. So we bought a standard (and cheap) transducer, and ran it in the opposite direction for which it was designed. This necessitated building our own driving/amplifying circuit (built by Jeff Brown).

The backside of the 2B unit showing the improved bleeder valve (used to bleed the air out of the bay during filling), and the compensation bladder (tygon tubing). The tubing is also used to fill the bay. The tubing is slightly compressed by the rubber band, keeping the internal pressure slightly higher then ambient pressure.