|

|

|

| Step 1: Drew cleaning the Axtrusion way |

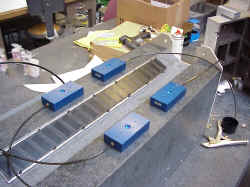

Step 2: the rough placement of the top bearings on the

way |

Step 3: The carriage is lower in place and the top

bearings positioned correctly. Then a vacuum is drawn through the top bearings to hold

them in place. |

|

|

|

| Step 4: Drew degreasing the surfaces of the bearing that

the epoxy will bond to. |

Step 5: Place side bearings in carriage |

Step 6: The carriage (w/ side bearings in place) is

lowered back on to the top bearings and the way. Fine adjustments are made in position of

the side bearings within the carriage. Then a vacuum is drawn through the side bearings to

secure them to the way. |

|

|

|

| Step 7: A piece of cardboard that is the correct

thickness to set the air gap between the motor coil and magnet track is placed between the

two. |

Step 8: Our hero (me) lowers the motor coil down onto the

cardboard space to set the correct air gap and place the carriage under the its actual

loading condition |

Step 9: Now a batch of epoxy is mixed up to hold the

bearings in place |

|

|

|

| Step 10: Drew injects the epoxy into the side bearing

pockets. |

Roger continues to inject epoxy into the side pockets. |

Drew inject epoxy into one of the top bearing pockets. |

|

|

|

| The six (6) Newway Bearings used in the Axtrusion

carriage. Four (4) 50 x 100mm and two (2) 75 x 150 mm. |

Look Mom!!! No Hands!!! The bearings can be

locked in place on the way by drawing a vacuum through them. This ensures that they

are accurately aligned with the way. |

|

|

| The semi-fluid viscosity epoxy was used so that it would not make a

huge mess when injected into the bearings and motor pockets. |

Look at that cool epoxy on the carriage (subliminal message, buy

Moglice buy Moglice... you are getting sleepy etc. etc.) |

Drew posing with his way cool bearings |